Monomex Machinery Technologies;Compounding & Extrusion

Research and Development

Manufacturing

Automation

Design

Process

Spare Parts & Service

Who We Are

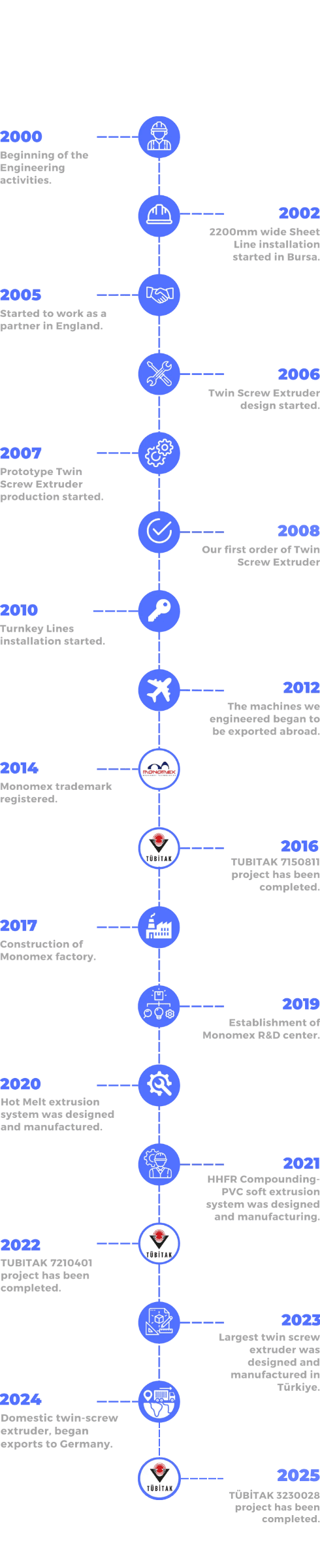

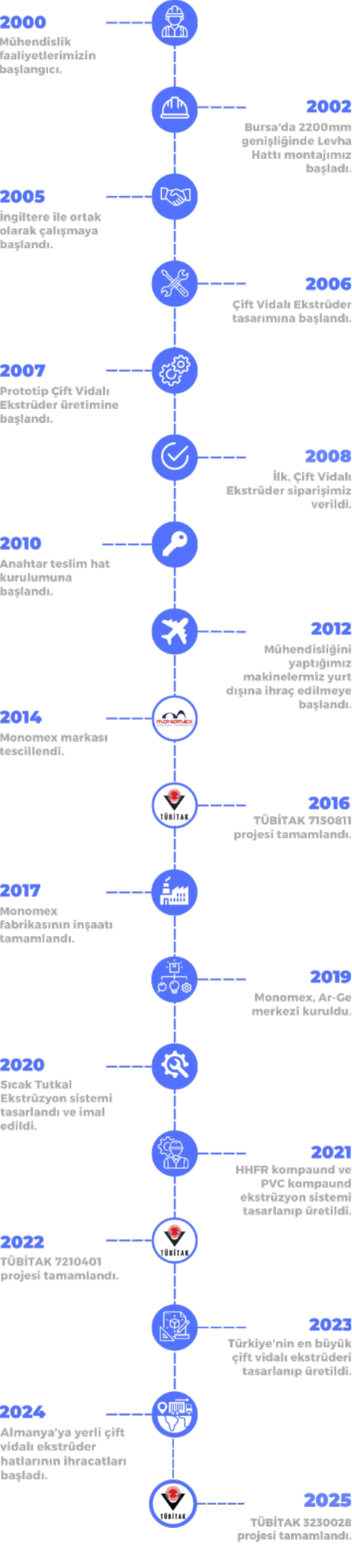

Monomex is a technology company powered by engineering precision, the dynamism of innovation, and the strength of teamwork. We specialize in the development of high-efficiency extrusion machinery and equipment across a wide industrial spectrum—most notably twin-screw extruder systems for compouding lines. More than just machines, we deliver a vision for production.

Effective Compounding & Extrusion Solutions with Monomex

We thoroughly analyze the unique needs of various industries and optimize processes with custom designs and high-precision systems. From plastics to food, pharmaceuticals to cosmetics, our equipment is engineered to deliver the ideal mix, superior dispersion, and precise parameter control—taking your production to the next level.

All our designs are developed in-house, and every stage of our production process is meticulously managed. This allows us to offer our clients not only technical assurance but also time efficiency. Our solutions go beyond industry standards, with high adaptability that enables rapid responses to changes in raw materials, formulations, or production conditions.

An Innovative Future with Monomex

At Monomex, we are committed to a vision that embraces not just today, but tomorrow. We extend our know-how and production capabilities beyond our own machines to deliver fast, economical, and effective solutions for different brands and systems across the industry.

We take responsibility in helping our customers achieve sustainable, profitable, and competitive manufacturing. Every partnership we build is designed to become a long-term collaboration.

If you're ready to start a new chapter in production, we invite you to become part of the Monomex family.

Spare Parts & Service

MONOMEX manufactures all spare parts for your extruder systems to the highest quality standards. With computer-aided designs and modern manufacturing techniques, we aim for 100% customer satisfaction. We also develop durable, custom screw elements compatible with various extruder types. Regular maintenance and professional service are essential for long-lasting machines—maintenance is always more economical than investing in new equipment.

PROCESS

The planning and installation of a complete compounding production line requires a customized engineering approach and in-depth process knowledge. At MONOMEX, we develop tailored designs and engineer every stage of the system—including material feeding, dosing, mixing, extrusion, and pelletizing—for optimal performance. We approach each project not just as equipment supply, but as a comprehensive production solution. With advanced engineering expertise and strong project management capabilities, we build efficient, scalable, and sustainable systems that meet our clients’ specific production needs.

DESIGN

If your production is unique, your design should be too. At MONOMEX, we turn your vision into reality. With custom-designed solutions tailored to your needs, we deliver more than just machines—we deliver differentiation. Our experienced engineering team combines functionality and aesthetics using the latest 3D design technologies. Leave conventional frameworks behind and discover unique designs that add real value to your production with MONOMEX.

MANUFACTURING

MONOMEX ensures uninterrupted production with high-quality, timely, and complete manufacturing solutions. We build all machines based on our own designs, guaranteeing full control over quality and technical compatibility. We also offer custom manufacturing, refurbishment, and spare parts solutions for non-MONOMEX systems, helping businesses stay operational and competitive.

RESEARCH-DEVELOPMENT

Technological expertise drives sustainable growth. Our R&D center develops high-value solutions tailored to customer needs. With our strong hardware and software capabilities, we keep your business ahead of the competition. Our lab-scale extruder is available for testing and innovation.

AUTOMATION

We’ve implemented all automation safeguards for seamless and safe operation. Your machine alerts you before maintenance is due—preventing unexpected downtime. Remote access allows real-time monitoring and control. Safety and consistent product quality are always our top priorities.