Recycling with Compounds

Recycling with CompoundsIn the recycling sector, exceptional investors need to make the right investment that will differentiate them from their competitors by recycling with the Monomex twin screw extruder.

Calcite Use In Plastic Industry

Calcite Use In Plastic IndustryCalcite is known as a filling material in the plastic industry and is often used by mixing (Compounding) into high proportions of plastic materials to cheapen plastic materials.

What is Compound?

What is Compound?Mixing different materials together under pressure by melting at high temperature is used as a Compound in the plastic industry.

Thermoset Extruder

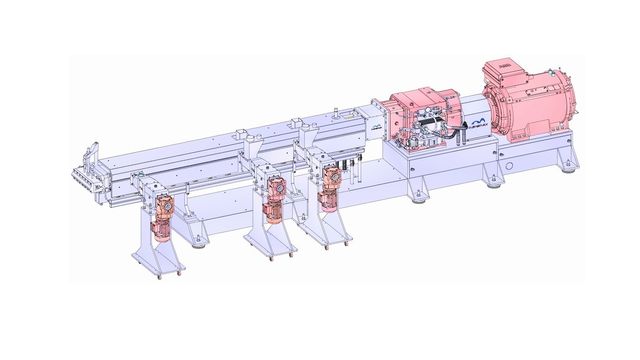

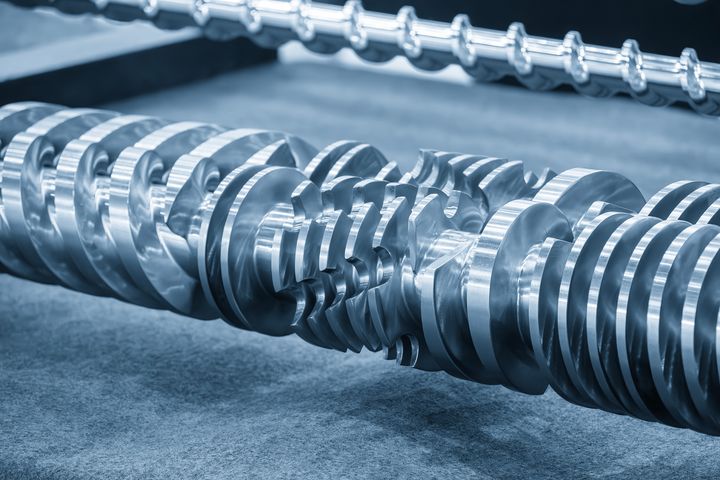

Twin screw extruders rotating in the same direction have the highest mixing capacity. Thus, the highest dispersion is achieved in the materials produced. Homogenous mixing and controlled pressure with equal temperature distribution produce the best material. The extruder screws clean each other while turning in the same direction, ensuring the best quality production.

It is possible to compound thermoset plastics with the best insulation and thermal properties in our machines working on the production of thermoset materials in excellent quality. Especially phenolites (bakelites), silicones, epoxies, aminos can be produced. The properties of thermoset materials are improved with twin screw extruders used in these productions. In addition, by adding some minerals and additives into thermoset resins, thermoset materials with new properties that increase production efficiency can be produced.

Creating a solution for the customer; developing a new plastics process...

The solidified phenol formaldehyde resin is compounded in the form of B BACALYTE with twin screw extruder and made ready for molding operation.

You can produce various formulations in a short time with the Monomex twin screw extruder that you will use in the development of thermosetting resins.

Our academic researches are carried out in the field of "Processing Thermosetting Materials in Automotive Design of Extrusion System to Improve Preforms to Obtain" Project No: 7210401, our years of experience in the production of thermoset materials has led to the development of superior quality twin screw extruder machines.

Advantages of Bakelite:

- Easy processing

- High electrical insulation.

- High dimensional stability of printed parts

- Brittleness and low impact resistance in thin parts

- Preservation of chemical properties even in freezing temperatures

- The printed parts have a smooth and shiny surface

- It maintains its dimensional stability up to 150C and no deformation occurs.

- With its low temperature conductivity, the handles and handles of pans, pots and pans remain cool to the touch.

- It can be used safely in parts that are likely to start a fire with its very difficult burning feature.

- High chemical resistance to alcohol, oils and many solvents and weak acids and alkalis.

Areas of Use:

- Aviation industry

- Electrical materials

- Kitchen utensils

- For military purposes

Have a question about our products and services? We are ready to listen your needs and discuss the possible solutions.

Energy Efficient + Durable + User Optimized

Extruder Systems

Monomer Extruder Makine Mühendislik San. ve Tic. Ltd. Şti. 2024 © All rights reserved.