Recycling with Compounds

Recycling with CompoundsIn the recycling sector, exceptional investors need to make the right investment that will differentiate them from their competitors by recycling with the Monomex twin screw extruder.

Calcite Use In Plastic Industry

Calcite Use In Plastic IndustryCalcite is known as a filling material in the plastic industry and is often used by mixing (Compounding) into high proportions of plastic materials to cheapen plastic materials.

What is Compound?

What is Compound?Mixing different materials together under pressure by melting at high temperature is used as a Compound in the plastic industry.

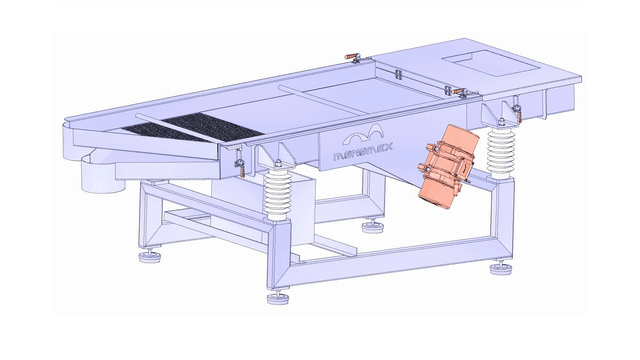

Vibrating Screener

Industrial screening is the most important equipment that determines product quality before packaging.

Industrial screening is mainly used in Compounding, Masterbatch, Recycling, Hot melt adhesive, food applications.

The products are processed in the industrial sieve, separated into the desired grain size, cleaned from dust, cooled and dried to the desired moisture content.

Especially in the production of plastic raw materials, the granular material obtained in the production of plastic raw materials is required to have a certain physical size in order to be used smoothly in the next operation. Because the presence of different sizes of material in the product causes disruption of the dosing flow and quality problems of the product.

In order to obtain the perfect product, it is necessary to produce at the desired ppm and standard deviation values. The most important quality factor here is the amount of moisture in the product.

The best way to separate the plastic granules from the dust that may occur during cutting or during transportation after cutting is to use a correct sieving machine.

Screening technology for better quality products.

Fluid Bed Dryer and Fluid Bed Coolers are used for efficient cooling of granules, especially in sensitive productions such as soft PVC. In these screens, the granules move on a layer of fluid air. Fluid Bed Dryer and Fluid Bed Coolers provide superior drying and cooling of products with vertical air flow.

Vibrating screens are used in high capacity production.

Linear moving vibrating screens move parallel to the floor, there is no bouncing movement in the granules. Thus, since there is no jumping movement, the rod-shaped parts cannot enter vertically through the holes and the dimensional equality of the products is not disturbed.

Advantages :

- It is ensured to obtain a single size product by separating products of different sizes due to the cutting system.

- The moisture in the granule is reduced to the desired ppm value.

- A cleaner product is obtained by separating the dust in the product.

- The sieved product is visually appealing,

- The granule can be cooled and packed with the desired physical properties.

- The cut product can be inspected by eye and hand before packaging.

- Particles larger than the desired size in the product can be separated.

Design Differences :

- Easy to clean

- Sieve replacement is simple and fast

- All surfaces in contact with the material are stainless,

- Different sizes of products can be processed with changeable sieve diameter.

- The amount of vibration can be adjusted and sieving can be done at different speeds.

Have a question about our products and services? We are ready to listen your needs and discuss the possible solutions.

Energy Efficient + Durable + User Optimized

Extruder Systems

Monomer Extruder Makine Mühendislik San. ve Tic. Ltd. Şti. 2024 © All rights reserved.