Recycling with Compounds

Recycling with CompoundsIn the recycling sector, exceptional investors need to make the right investment that will differentiate them from their competitors by recycling with the Monomex twin screw extruder.

Calcite Use In Plastic Industry

Calcite Use In Plastic IndustryCalcite is known as a filling material in the plastic industry and is often used by mixing (Compounding) into high proportions of plastic materials to cheapen plastic materials.

What is Compound?

What is Compound?Mixing different materials together under pressure by melting at high temperature is used as a Compound in the plastic industry.

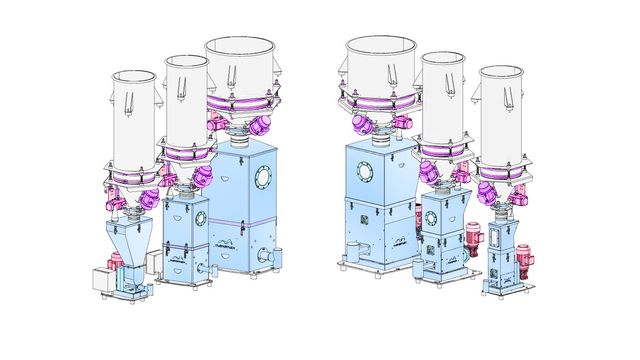

Loss in Weight Gravimetric Feeder

Monomex loss in weight with continuous flow gravimetric dosing, extruders do not have to pre-mix to feed the material at any rate. Materials from extruders fed at more accurate rates and more precise flow rates are of superior quality. Especially twin screw extruders by increasing the capacity to work more efficiently.

Our reliable and accurate gravimetric feeders are ideal for dosing a wide range of bulk materials. All our gravimetric feeders are supplied with state-of-the-art microprocessor-based controls with easy-to-use operator interfaces.

Monomex Gravimetric dosing systems are today an indispensable part of production facilities managed for quality production.

Our intelligent systems allow a production line with single or multiple feeders to be controlled and communicate directly with most host/PLC systems.

- Monomex's unique design system has a significant advantage over conventional dosing devices.

- The formula of the material processed in the machines is hidden. Only the personnel who know the password of the formula page can see and refresh the formulas.

- The amount of material entering machines is always the same as automatic weighing.

- The formula can be changed during production.

- Total working capacity can be seen instantly. In addition, how many hours the extruder worked in the material is evident in kg.

- Production accelerates and loyalty to man is eliminated.

- The user has the opportunity to clean and change the material within one minute with quick reservoir change.

- The dosing screw can be changed with a single hand and thus the process is continued immediately for every material that is required to dosing.

Have a question about our products and services? We are ready to listen your needs and discuss the possible solutions.

Energy Efficient + Durable + User Optimized

Extruder Systems

Monomer Extruder Makine Mühendislik San. ve Tic. Ltd. Şti. 2024 © All rights reserved.