Recycling with Compounds

Recycling with CompoundsIn the recycling sector, exceptional investors need to make the right investment that will differentiate them from their competitors by recycling with the Monomex twin screw extruder.

Calcite Use In Plastic Industry

Calcite Use In Plastic IndustryCalcite is known as a filling material in the plastic industry and is often used by mixing (Compounding) into high proportions of plastic materials to cheapen plastic materials.

What is Compound?

What is Compound?Mixing different materials together under pressure by melting at high temperature is used as a Compound in the plastic industry.

Education & Maintenance & Service

Our people are the guarantee of the future, and our people are the guarantee of training from the experts.

You can rely on the experts in the Monomex Engineering team to make sure your machines are optimally selected for production.

You can contract for consulting, engineering, training, maintenance and service to work efficiently and smoothly.

Machines have an infinite lifespan. All you need to do is maintain the machines and replace worn parts. Monomex not only provides pre-sales support, but extends its support to after delivery and the entire lifetime of the machines. Call us anytime...

Be a winner; maintenance is cheaper than buying a new one.

Every machine generates vibrations during operation. The amount of this vibration must be within standards. Non-standard vibrations or machine displacements that occur over time cause the alignment of the machines to deteriorate. You can prevent bigger failures that may occur by having your machines periodically checked and scheduled maintenance.

Aligning your machines according to the correct tolerances, detecting vibrations, in other words, having predictive maintenance quickly pays for itself with less spare parts cost, less production loss, lower electricity bills and more energy efficiency.

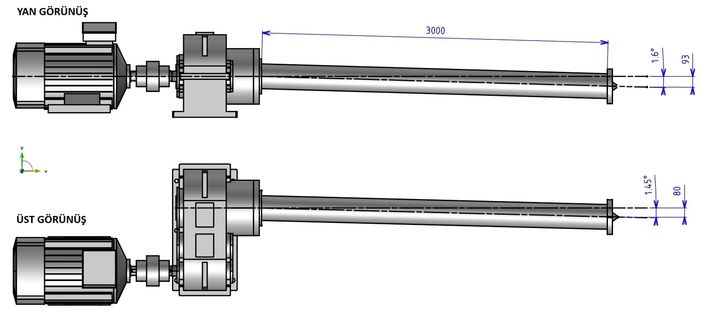

In extruders, the connection points of the barrel and reducer must be on the same axis. As in the picture, the screw that is not on the same axis breaks at the reducer connection point. Or the screw that is not on the axis rubs against the barrel and causes rapid wear. Friction causes abrasion, excessive electricity consumption and mechanical stress, resulting in malfunctions such as gearbox gear breakage, shaft cutting. Call us immediately to avoid sudden stops during production...

Our Services;

- Extruder barrel alignment

- Coupling Alignment,

- Vibration Measurements,

- Machine Balancing,

- Thermal Measurements,

- Electrical Measurements,

- Geometric Alignment,

- Software solutions with Industry 4.0.

Advantages;

- Increases the lifetime and efficiency of extruders and other process machines.

- Reduces machine breakdowns and prevents unplanned downtime and therefore production disruption.

- Increases the service life of rotating equipment, motors and auxiliary accessories.

- Increases production efficiency by reducing disruptions in production flow.

- Reduces machine breakdowns and prevents unplanned stoppages and therefore disruption of production.

- Reduces energy consumption due to amperage increases.

- Eliminates unnecessary spare and stock parts costs.

Have a question about our products and services? We are ready to listen your needs and discuss the possible solutions.

Energy Efficient + Durable + User Optimized

Extruder Systems

Monomer Extruder Makine Mühendislik San. ve Tic. Ltd. Şti. 2024 © All rights reserved.