Recycling with Compounds

Recycling with CompoundsIn the recycling sector, exceptional investors need to make the right investment that will differentiate them from their competitors by recycling with the Monomex twin screw extruder.

Calcite Use In Plastic Industry

Calcite Use In Plastic IndustryCalcite is known as a filling material in the plastic industry and is often used by mixing (Compounding) into high proportions of plastic materials to cheapen plastic materials.

What is Compound?

What is Compound?Mixing different materials together under pressure by melting at high temperature is used as a Compound in the plastic industry.

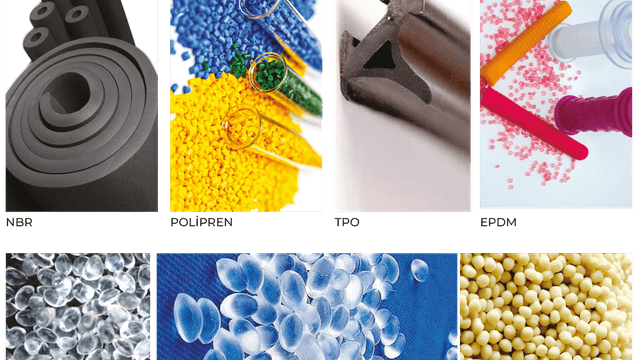

Thermoplastic Elastomers

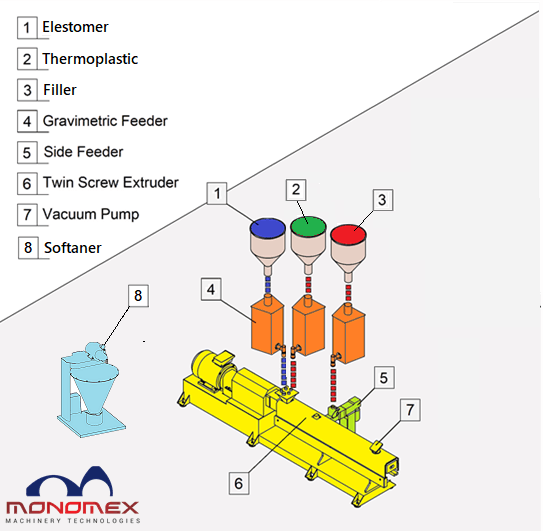

The production of thermoplastic elastomers is done in twin-screw co-rotate extruders. Thermoplastic elastomers (TPEs) are high-strength products that combine plastic and elastomer properties. Major Thermoplastic Elestomers can be given as examples: Thermoplastic Vulcanizates (TPV), Styrene Block Copolymers (TPE-S), Thermoplastic Polyurethanes (TPU), Thermoplastic Polyolefin Blends (TPO), Polyamides (PEBA), Copolyesters (COPE). The performance characteristics of TPE are very similar to commercial rubbers. Its elastomeric phase enables it to exhibit rubbery properties such as elastic recycling and softness.

On the other hand, the thermoplastic phase is processed by extrusion, injection molding, blow molding, etc. They allow processing with classical plastic processing methods such as plastic processing and the use of equipment used in thermoplastics, and are fully recyclable.

Monomex twin screw extruders have been designed so that you can produce creative solutions with specially developed TPEs in your existing and new applications. To obtain correct results, it is necessary to work with Monomex twin screw extruders.

Example Thermoplastic elastomer production formula;

The formulation required to make TPE-V compound with real 50-60 Shore-A hardness is as follows.

EPDM%28 + PP%20 + Oil%35 + Filler%12 + Additive%5

Have a question about our products and services? We are ready to listen your needs and discuss the possible solutions.

Energy Efficient + Durable + User Optimized

Extruder Systems

Monomer Extruder Makine Mühendislik San. ve Tic. Ltd. Şti. 2024 © All rights reserved.