Recycling with Compounds

Recycling with CompoundsIn the recycling sector, exceptional investors need to make the right investment that will differentiate them from their competitors by recycling with the Monomex twin screw extruder.

Calcite Use In Plastic Industry

Calcite Use In Plastic IndustryCalcite is known as a filling material in the plastic industry and is often used by mixing (Compounding) into high proportions of plastic materials to cheapen plastic materials.

What is Compound?

What is Compound?Mixing different materials together under pressure by melting at high temperature is used as a Compound in the plastic industry.

Ask The Expert

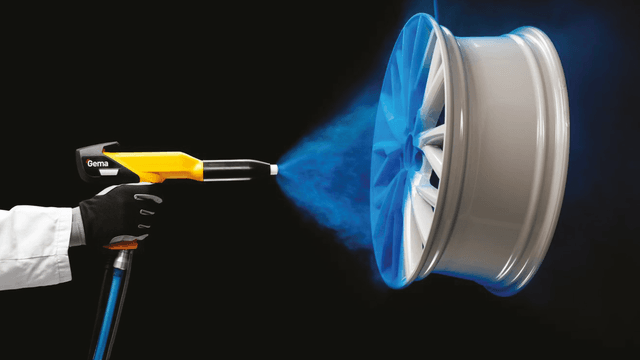

How do you choose the right ingredient dosing system for your application? Selection of Dosing Systems…

The feeding systems used in many industries are used for the processing of volumetric, i.e. volumetrically discharged materials. Depending on the movements of the drive units during production operations, valve, screw, conveyor or similar feeding systems are used. In these systems, the supply is homogeneous, that is, it does not constantly occur in a certain constant flow. This problem causes differences in the material structure. Since the materials are not distributed in a homogeneous structure, they cannot meet the necessary physical and chemical properties. Many R&D studies have been carried out to overcome this Deciency.

Both the development of the properties of electrical components, software and mechanical developments have contributed to the development of new supply systems. Engineers looking for a solution have been able to calculate the flow rate by calculating the weight loss in the flow according to time with the continuous flow of the material in the hopper. The feeding systems made in this way are also called with ”Weight Loss".

Methods that are cheaper and have more deviations have also been developed for different industrial applications. In this system, which is called “Weight Gain” by users, the spilled materials are poured into a hopper and a single weighing unit is used. In this feeding system, all the materials are weighed in a single hopper and deposited by pouring them on top of each other. During deposition, materials with different specific gravity in the chamber move with the effect of gravity and accumulate towards the lower part of the chamber. This accumulation prevents the formation of a homogeneous structure and requires a mixing process again. Especially in mixing machines such as Banbury, since the mixture is made in a single chamber, the mixed mass may become homogeneous by a certain amount. Another disadvantage is that the weight accuracy of the material being poured into a chamber on the load cells is a function of the full-scale load of the container being poured plus the product. In other words, a system designed to add both macro and micro components to the same container may not be able to accurately detect smaller quantities.

If a continuous flow at pressure with a more homogeneous structure and controlled temperature in the mixture is desired, excellent dispersion can be achieved in the only solution twin screw extruder. The twin screw extruder feeding system used to make production faster and in a shorter time is a gravimetric feeding system with only Weight Loss.

In order to ensure that the overall feeding process is carried out in the most efficient way, it is important that all these options are discussed with the dosing system manufacturer.

Have a question about our products and services? We are ready to listen your needs and discuss the possible solutions.

Energy Efficient + Durable + User Optimized

Extruder Systems

Monomer Extruder Makine Mühendislik San. ve Tic. Ltd. Şti. 2024 © All rights reserved.