Recycling with Compounds

Recycling with CompoundsIn the recycling sector, exceptional investors need to make the right investment that will differentiate them from their competitors by recycling with the Monomex twin screw extruder.

Calcite Use In Plastic Industry

Calcite Use In Plastic IndustryCalcite is known as a filling material in the plastic industry and is often used by mixing (Compounding) into high proportions of plastic materials to cheapen plastic materials.

What is Compound?

What is Compound?Mixing different materials together under pressure by melting at high temperature is used as a Compound in the plastic industry.

Extrusion Melt Pumps

Extrusion gear pumps increase the outlet pressure in extruders and make it more uniform. Thus, the material coming out of the extruder has an excellent pressure stability. It is the only solution for all applications that require high pressure at the extruder outlet. Moreover, using a melt gear pump is the only solution to produce within tolerances in productions where thickness variations are important.

Monomex gear pumps are installed between the extruder and the mold on the production line. This combination eliminates vibration and output fluctuations. Very stable and constant flow conditions pave the way to excellent product quality. Whether processing low viscosity materials, achieving high pressure in the extruder or processing sensitive plastics, we ensure that processes are optimized.

With the MEX DP gear pump, instead of investing in a new Extruder, by adding an additional gear pump, both a higher quality material and an increase in capacity can be achieved.

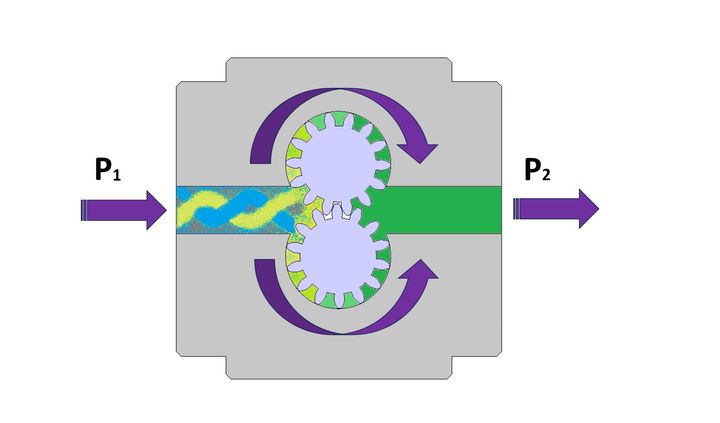

What is an extruder gear pump, melt pump, extruder pump or melt pump? How does it work? What are the advantages?

To explain it briefly; It is a machine that works in front of the extruders and has many advantages. Gear pumps have a great importance and place in areas where polymer chemistry and process are valid. Nowadays, gear pumps can be used on newly manufactured extruders or by being retrofitted to existing extruders. In both cases, gear pump; It is used to increase production, obtain smoother products, save energy, provide flexibility and improve product quality. General areas of use are monofilaments, lamination, sheet production for thermoforming purposes, foil, coating, profile, pipe, cable extrusion, etc. can be counted as.

Advantages :

- Pressure variations caused by irregular feeds are reduced.

- Extruder outlet pressure decreases.

- Extruder main motor current decreases.

- Extruder outlet temperatures decrease.

- More stable product production is ensured.

- Extruder capacity increases.

- Product quality increases.

- Provides a more profitable production.

Design Differences:

- Anti-cavitation channel and gear geometry

- Minimum pressure loss

- Longer lasting gears with strong structure

- Better temperature control with extra cooling channels

- Gear profile developed for precision production

- Minimum deviation in thickness variations

Have a question about our products and services? We are ready to listen your needs and discuss the possible solutions.

Energy Efficient + Durable + User Optimized

Extruder Systems

Monomer Extruder Makine Mühendislik San. ve Tic. Ltd. Şti. 2024 © All rights reserved.