Recycling with Compounds

Recycling with CompoundsIn the recycling sector, exceptional investors need to make the right investment that will differentiate them from their competitors by recycling with the Monomex twin screw extruder.

Calcite Use In Plastic Industry

Calcite Use In Plastic IndustryCalcite is known as a filling material in the plastic industry and is often used by mixing (Compounding) into high proportions of plastic materials to cheapen plastic materials.

What is Compound?

What is Compound?Mixing different materials together under pressure by melting at high temperature is used as a Compound in the plastic industry.

Spare Parts

The most important spare parts in extruders are extruder screws. Extruder screws should be measured every 3 to 12 months depending on their production and their wear amount should be kept under control.

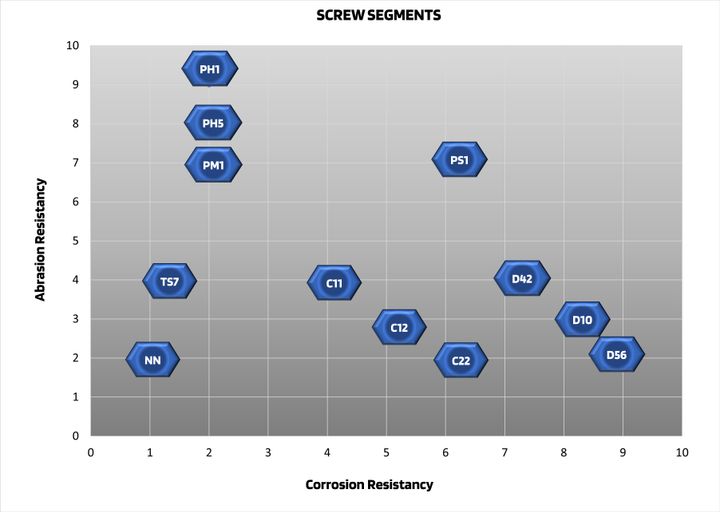

In extruders, materials are processed between screw and barrel. Screws and barrels in contact with corrosive or abrasive products are under constant wear and pressure. Extruder elements such as screws, barrels, shafts, couplings, molds working under high pressure, torque and temperature are critical parts. These critical parts need to be accessed in a short time in order to prevent long-term production downtime.

Monomex manufactures extruder screw elements in-house. The extruder screws we manufacture work perfectly starting from 16mm up to 320mm. With the advantage of being a manufacturer, extruder screw delivery time to our customers is 2-4 weeks. Our in-house stock of more commonly used or standard screw elements is constantly replenished for next day delivery service.

In addition to the Monomex manufacturing capability, we can also design new elements to meet specific requirements or design custom solutions for your production.

Quality Shaft is made of quality material.

With the technology we use, the screw surfaces that come into contact with the material processed in the extruder have the quality of a ground surface. Thus, there is no striped, notched surface caused by milling. The flow of the melt material is also linear on the brighter and slippery surface. There is no overheating due to irregular flow in the processed material. Mechanical strength is higher. No cracking and breakage due to notch effect.

We use specially heat-treated, high-alloyed tool steel for the shafts as standard for all machines and spare parts. Be sure to spare your shafts that are most likely to be damaged in the extruder.

Advantages:

- Manufacturing with new technology

- Grinded surface quality with improved production methods

- Use of high quality steel PM, HIP materials

- Flexible solutions according to customer requirements

- Customized design and manufacturing capability

- Cost-effectiveness with innovative processes

- Fast delivery with short response times

Design differences:

- Parts with longer lifetime

- Surface smoothness to improve the quality of the processed product

- Alternative solutions according to the product

- Designs based on advanced engineering and scientific calculations

Have a question about our products and services? We are ready to listen your needs and discuss the possible solutions.

Energy Efficient + Durable + User Optimized

Extruder Systems

Monomer Extruder Makine Mühendislik San. ve Tic. Ltd. Şti. 2024 © All rights reserved.