Recycling with Compounds

Recycling with CompoundsIn the recycling sector, exceptional investors need to make the right investment that will differentiate them from their competitors by recycling with the Monomex twin screw extruder.

Calcite Use In Plastic Industry

Calcite Use In Plastic IndustryCalcite is known as a filling material in the plastic industry and is often used by mixing (Compounding) into high proportions of plastic materials to cheapen plastic materials.

What is Compound?

What is Compound?Mixing different materials together under pressure by melting at high temperature is used as a Compound in the plastic industry.

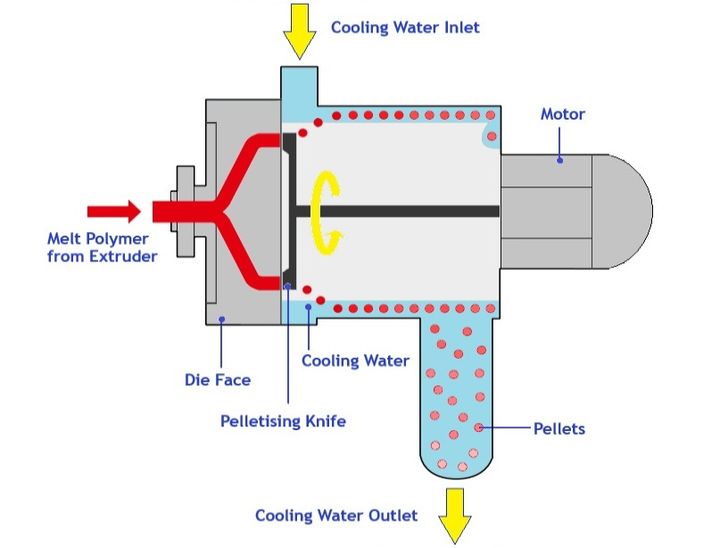

Water Ring Pelletizers

Water Ring Granule Cutting is used to bring the material coming out of the extruder in molten form in sphere form. The molten material coming out of the holes in the extruder exit mold is cut and dispersed by the rapidly rotating blade. It falls into the water flowing in a ring around the blade, cools and takes the shape of a sphere. Since in this cutting system, water flows in a ring around the blade, this cutting system is called Water Ring Granule Cutting.

The hot die face pelletizer systems can be used for almost all conventional thermoplastic melts with the exception of PA 6.6, PET and PP melts with an MFI (Melt Flow Index) of over 250g/10 min.

Direct Drive technology for better quality products.

- Maintenance-free and smooth mechanical action of knife head pressure

- Knife head drive shaft with direct drive

- Outstanding cutting precision in combination cutting pressure setting

- Pelletiser knives and die face have a long service life

Advantages :

- It is the only cutting method in irregular flow. It is the only cutting method that can be used if the pressure and flow rate changes of the material processed in your extruder are too high. If the material processed from the extruder exits at an irregular flow rate, the best solution method is to use a water ring cutting system.

- Investment and operating costs are very low.

- Since it takes up little space, it saves space in the factory.

- Energy consumption is very low since the heat transfer to the cooling water is very low. Thus, you can obtain products with more competitive prices.

- Ergonomic. Personnel gets less tired with less effort.

- Work safety has been increased.

Design Differences :

- A more homogenous product can be obtained.

- Process water consumption is reduced.

- The processed material changes are such that minimum waste is given.

- New type blades with increased durability are used.

- It is easier to use.

Have a question about our products and services? We are ready to listen your needs and discuss the possible solutions.

Energy Efficient + Durable + User Optimized

Extruder Systems

Monomer Extruder Makine Mühendislik San. ve Tic. Ltd. Şti. 2024 © All rights reserved.